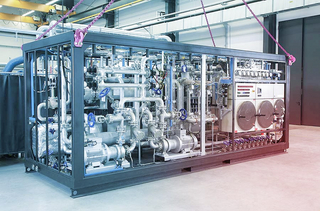

Heating and cooling systems from the process cooling unit line of the type series SUK always consist of the modules compressor, pump, expansion vessel, evaporator and condenser. Depending on the lowest working temperature, single stage (down to -35 °C) or two stage compressors (down to -50 °C) are used. At very low temperatures down to -100 °C, two cooling systems in cascade connection are used. Cooling of the refrigerant condenser is done with cooling water or air. Output is regulated infinitely and precisely by injection control. If several compressors are used, an incremental switch ensures energy-saving, low-wear, partial load operation (automatic compressor control). With an electric heater or steam-heated heat exchanger, the SUK type series can be used for temperatures from -100 to 150 °C. Pre-cooling with on-site brine or air can be easily implemented using the modular system. The application alone decides whether or not a cold accumulator is beneficial.

TECHNICAL DATA FOR LAUDA PROCESS COOLING UNITS

| Features | SUK 150 W/L(Ex) | SUK 250 W/L(Ex) | SUK 350 W/L(Ex) | SUK 400 W/L(Ex) | SUK 600 W/L(Ex) | SUK 1000 W/L(Ex) |

|---|---|---|---|---|---|---|

| Heat carriers | Water, water/glycol, thermal oil, special liquids | |||||

| Working temperature (°C) | - 40 ... 150 | - 50 ... 150 | - 70 ... 150 | - 100 ... 150 | - 100 ... 150 | - 100 ... 150 |

| Pump output (m³/h) | 0,5 … 2 | 2 … 6 | 2 ... 20 | 4 ... 30 | 5 ... 50 | 10 ... 80 |

| Heating output (kW) | up to 9 | up to 18 | up to 50 | up to 60 | up to 120 | up to 240 |

| Single-stage compressor | ||||||

| Cooling output at 20 °C (kW) | up to10 | up to 20 | up to 50 | up to 150 | up to 300 | up to 400 |

| Cooling output at 0 °C (kW) | up to 5 | up to 15 | up to 35 | up to 120 | up to 240 | up to 300 |

| Cooling output at - 20 °C (kW) | up to 3 | up to 6 | up to 18 | up to 60 | up to 120 | up to 180 |

| Cooling output at - 40 °C (kW) | up to 1 | up to 2 | up to 7 | up to 45 | up to 90 | up to 120 |

| Two-stage compressor | ||||||

| Cooling output at - 50 °C (kW) | up to 1 | up to 4 | up to 35 | up to 70 | up to 90 | |

| Two-circuit cascade | ||||||

| Cooling output at - 60 °C (kW) | up to 3 | up to 25 | up to 50 | up to 70 | ||

| Cooling output at - 70 °C (kW) | up to 2 | up to 10 | up to 20 | up to 35 | ||

| Cooling output at - 80 °C (kW) | up to 0.5 | up to 5 | up to 10 | up to 20 | ||

| Min. dimension (mm) | 400 x 800 x 1000 | 500 x 1000 x 1500 | 800 x 1700 x 1500 | 1000 x 1500 x 1900 | 1500 x 2200 x 2000 | 1500 x 2200 x 2000 |

| Max. dimension (mm) | 500 x 1000 x 1500 | 600 x 1500 x 1500 | 1000 x 1500 x 1900 | 1300 x 1900 x 2000 | 200 x 2500 x 2000 | 2000 x 2500 x 2000 |

| Features | KH 150 W/L(Ex) | KH 250 W/L(Ex) | KH 350 W/L(Ex) | KH 400 W/L(Ex) | KH 600 W/L(Ex) | KH 1000 W/L(Ex) |

|---|---|---|---|---|---|---|

| Heat carriers | Thermal oil, special liquids | |||||

| Working temperature (°C) | - 40 ... 250 | - 50 ... 250 | - 70 ... 250 | - 100 ... 250 | - 100 ... 250 | - 100 ... 400 |

| Pump output (m³/h) | 0.5 … 2 | 2 … 6 | 2 ... 20 | 4 ... 30 | 5 ... 50 | 10 ... 80 |

| Heating output (kW) | up to 9 | up to 18 | up to 50 | up to 60 | up to 120 | up to 240 |

| Single-stage compressor | ||||||

| Cooling output at 20 °C (kW) | up to10 | up to20 | up to50 | up to150 | up to300 | up to400 |

| Cooling output at 0 °C (kW) | up to 5 | up to 15 | up to 35 | up to 120 | up to 240 | up to 300 |

| Cooling output at - 20 °C (kW) | up to 3 | up to 6 | up to 18 | up to 60 | up to 120 | up to 180 |

| Cooling output at - 40 °C (kW) | up to 1 | up to 2 | up to 7 | up to 45 | up to 90 | up to 120 |

| Two-stage compressor | ||||||

| Cooling output at - 50 °C (kW) | up to 1 | up to 4 | up to 35 | up to 70 | up to 90 | |

| Two-circuit cascade | ||||||

| Cooling output at - 60 °C (kW) | up to 3 | up to 25 | up to 50 | up to 70 | ||

| Cooling output at - 70 °C (kW) | up to 2 | up to 10 | up to 20 | up to 35 | ||

| Cooling output at - 80 °C (kW) | up to 0.5 | up to 5 | up to 10 | up to 20 | ||

| Min. dimension (mm) | 500 x 800 x 1000 | 600 x 1000 x 1500 | 800 x 1700 x 1500 | 1000 x 1500 x 1900 | 1500 x 2200 x 2000 | 1500 x 2200 x 2000 |

| Max. dimension (mm) | 600 x 1000 x 1500 | 800 x 1700 x 1500 | 1000 x 1500 x 1900 | 1300 x 1900 x 2000 | 2000 x 2500 x 2000 | 2000 x 2500 x 2000 |

Your advantages at a glance

Digital temperature controllers

for the control of consumers/product temperature, as well as outflow temperature

Energy-efficient cooling system with high dynamic

Thanks to modern refrigeration modules for the best possible configuration of compressor and output

Automatic shut-off valve in the cooling water inflow

To prevent contamination of the heat exchanger

Hermetic model without gaskets

So that oil and water are not mixed

Infinitely controlled electrical stainless steel heating bodies

This way, the heating output can be adapted to the actual energy requirement

FAT (Factory Acceptance Test) in the customer's presence

For checking that the systems are designed for customer requirements and initial training and test run even before delivery