In the automotive industry, test benches, aging tests, quality control and the examination of various engine components are part of daily business. Therefore, for example, you must always be able to rely on correct temperatures during testing, enabling accurate assessment and validation of the device under test. With the temperature control units for the automotive industry from our portfolio, you can achieve this. Our product range includes a large number of units to keep your temperature control processes in the automotive industry up to date.

Examples

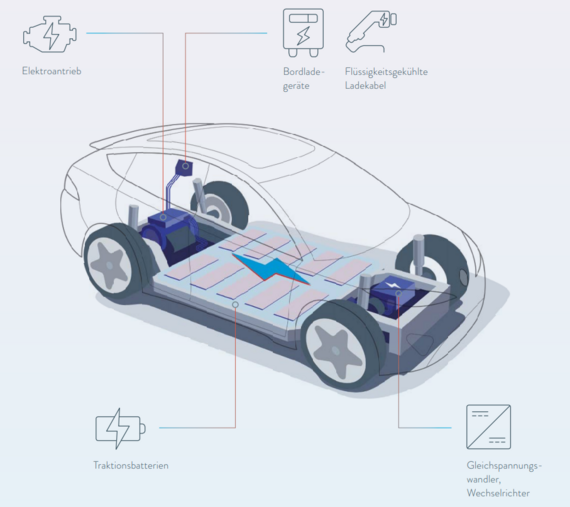

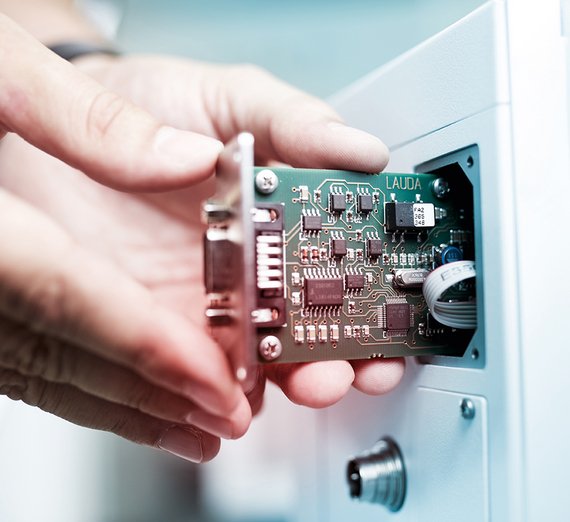

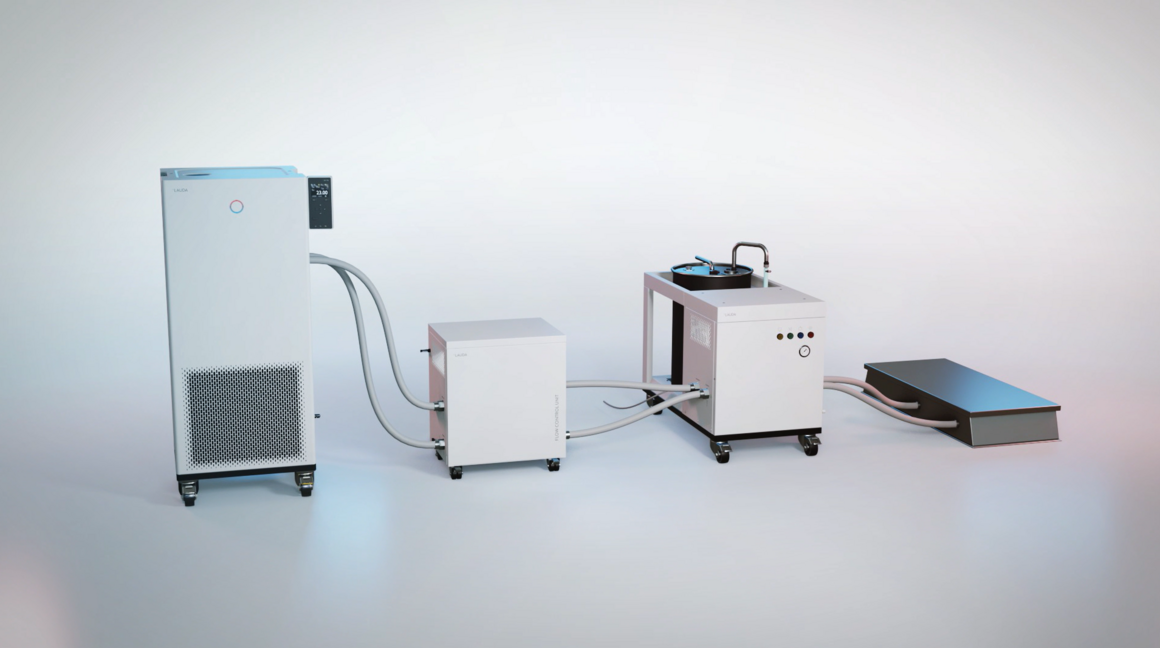

Integral process thermostats are used in the automotive industry and by a large number of testing service providers to test batteries, power electronics and eDrives, often in combination with LAUDA flow control or LAUDA filling and draining unit.

Our Ultracool circulation chilllers are perfect for providing central cooling water for Integral process thermostats and ensure a high cooling capacity - even in continuous operation. They are suitable for outdoor installation and also have a temperature monitor that reliably protects the heat exchanger.

LAUDA plans and builds systems precisely in accordance with the customer's wishes: process-oriented, made-to measure and precisely in accordance with the regulations, and in compliance with the strict safety standards. Since the requirements for constant temperature equipment are continuously growing, the modern LAUDA heating and cooling systems are also flexible as far as expansion and modification are concerned.