LAUDA offers temperature control solutions for the hydrogen sector along the entire value chain - from the production of hydrogen to the development and testing of fuel cells to the refueling of vehicles. Our process cooling systems and equipment temper electrolysers and compressors, assist in the drying and purification of the hydrogen and are responsible for pre-cooling it to -40 °C for the refueling process. They are also used in test stands for fuel cells' development and quality control.

Hydrogen plays a decisive role in overcoming the challenges of energy transition. Whether used to store energy or for future mobility, hydrogen is an environmentally friendly solution with enormous potential. However, it is important that green hydrogen is produced efficiently using climate-neutral methods. The benefits of hydrogen as an energy source of the future are significant: It has a high energy content of 33 kWh/kg, in contrast to diesel fuel, which has only 10 kWh/kg. Compared to combustion engines, a 5 kg tank of hydrogen can reach ranges of around 650 km in conjunction with an efficient system of fuel cells and an electric drive. Hydrogen electrolysis is also an excellent way to store surplus electricity from renewable energies. LAUDA's innovative constant temperature solutions address challenges in handling hydrogen during refueling.

LAUDA's cooling systems significantly enhance hydrogen production efficiency, globally utilized for years. They play a crucial role in electrolyzer cooling, as well as hydrogen drying and purification. Our customers rely on the new generation of LAUDA Ultracool devices.

Post-production, hydrogen undergoes compression, facilitated by LAUDA Ultracool devices. Their connectivity enables seamless interconnection, monitoring, maintenance, and data analysis, making LAUDA cooling solutions pivotal for reliable and efficient hydrogen production.

Energy-efficient

Developed with a focus on energy efficiency, the LAUDA Ultracool circulation chillers make a pivotal contribution to reducing your operating costs. Compared to classic circulation chillers, the devices can reduce energy costs by up to 50 percent, depending on the operating conditions. This plays a very important role in increasing overall efficiency, especially in hydrogen production.

Optimized for Industry 4.0

Thanks to the innovative operating concept, the LAUDA Ultracool circulation chillers can be conveniently monitored and controlled from a distance – via a connected control panel or the integrated web server on a PC or laptop. A connection to LAUDA.LIVE allows device data to be saved, analyzed and used for remote maintenance.

Advanced technology for a broad range of applications

Extensive technical innovation and a significantly expanded range of functions characterize the various LAUDA Ultracool devices and additional equipment options. Custom options and a wide cooling output range make LAUDA Ultracool circulation chillers the ideal solution for a broad range of hydrogen-based applications.

Are you looking for temperature control solutions for hydrogen? Then contact us.

Together, we will find the right solution for your requirements.

Decades of experience

For many years, LAUDA has been a leading provider of innovative constant temperature technology in test bench construction for the automotive, electrical and aviation industries, and can now apply this extensive experience to the development of components and systems for the hydrogen industry. The area of testing not only extends to hydrogen vehicles, but also to electrolyzers, filling stations, tanks and compressors.

Development of hydrogen technology

Components designed to interact with hydrogen undergo rigorous testing in specialized environments to guarantee optimal functionality and reliability during operation. One vital part of material testing is simulating extreme environmental conditions across different temperature ranges to increase the quality and safety of hydrogen technologies.

Testing in the development of hydrogen component

Renowned quality

The Integral product line has proven itself in a wide variety of industries and applications for more than 20 years. Several thousand installations ensure the extensive testing and development of innovative components and systems on test benches in the automotive, electronics and aviation industries.

Testing hydrogen components

LAUDA Integral process thermostats are used in the automotive industry and by a large number of testing service providers to test fuel cells, components and hydrogen combustion engines, often in combination with LAUDA flow control units or LAUDA filling and draining systems.

Powerful and dynamic

With a maximum cooling output of 28 kW, a maximum heating output of 24 kW, and a working temperature range of −90 to 320°C, our integral process thermostats perform outstandingly well in every application.

Maximum connectivity

Fit for the future and ready for LAUDA.LIVE: Integral constant temperature systems can be flexibly integrated in various communication scenarios thanks to an integrated web server, monitoring and control via PC or mobile devices, and the modular interface concept.

User-friendly operation

Softkey control directly on the device, remote control via touch display or mobile devices mean that it has never been easier to control your constant temperature applications according to your requirements. The new Integral devices determine the optimum control parameters for the application at the touch of a button, and the temperature control media can be selected to ensure safe and optimum use of the liquid. The high-precision flow control unit extends your options and ensures you have control over your test and production processes.

Are you looking for temperature control solutions for hydrogen? Then contact us.

Together, we will find the right solution for your requirements.

Our state-of-the-art cooling solutions for hydrogen filling stations make sure that the hydrogen infrastructure operates smoothly and efficiently. Since 2015, we have been developing and continuously optimizing our cooling systems through pioneering work. The modular systems are extremely flexible and can be adapted or extended to suit different pressure and temperature requirements. Our cooling solutions are utilized not only in conventional filling stations for both passenger and heavy-duty transport vehicles but also in tube trailers and for refueling trains. One key feature of our solutions is the efficient cooling of the compressors required to generate pressure by our LAUDA Ultracool process circulation chillers. We are therefore able to offer a holistic solution from a single source.

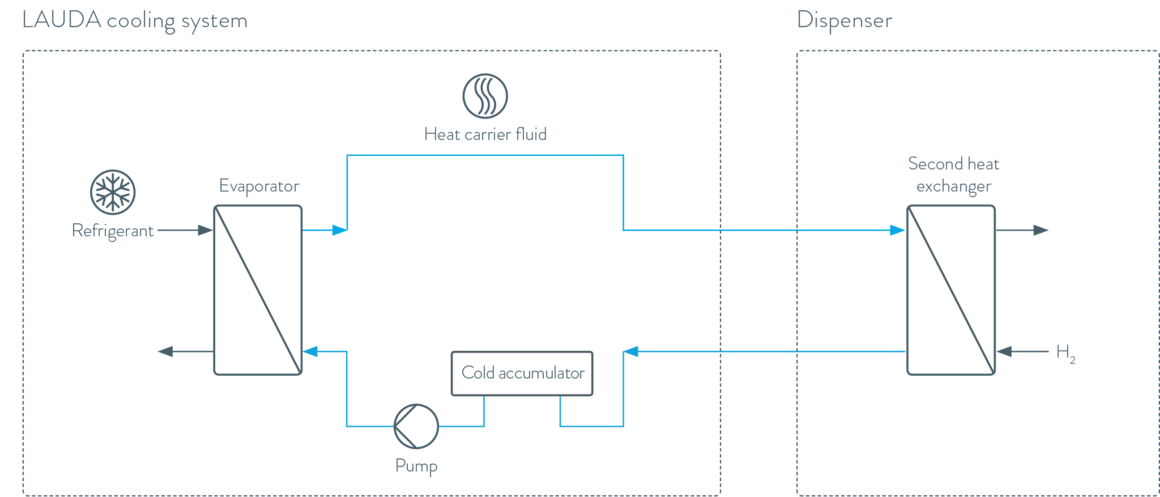

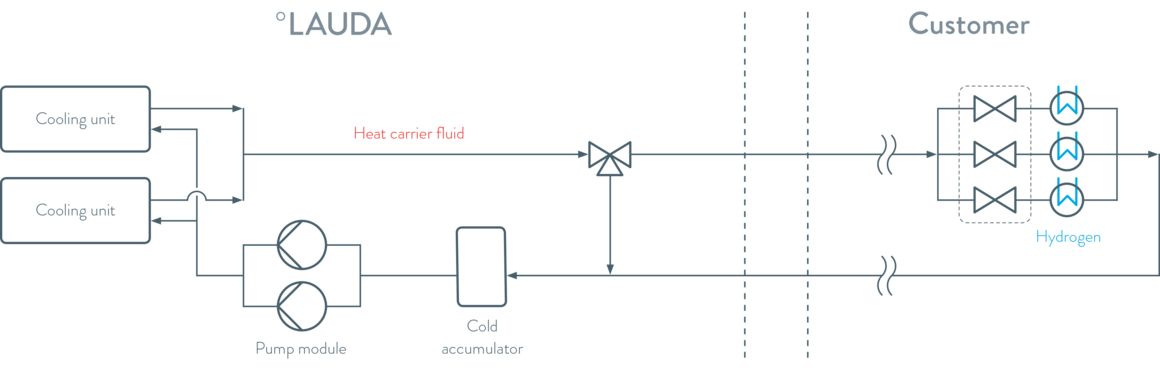

Benefits of indirect cooing

Cooling unit is a direct evaporator that can have a redundant design to ensure maximum reliability and enable continued operation of the tank system, even during service campaigns. It also offers better partial load efficiency, which makes sense from an energy perspective, especially when demand is low. It is therefore possible to install just one cooling unit in a refilling station and add another module to the system as demand increases. The cooling unit has two refrigerant circuits in a cascade connection, which are operated with natural refrigerants.

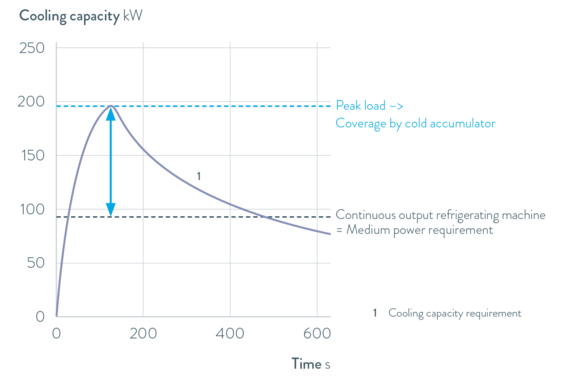

Three-way valve, designed primarily to pre-cool the cold accumulator in standby mode. Even if there is a decrease in load at the fuel pump, the excess cooling capacity can be used to regenerate the cold accumulator during the refueling process in order to start subsequent refueling directly without a break.

A wide variety of protocols can be installed at the fuel pumps, for example, 1x350 bar and 2x700 bar for LDV and HDV. One possible solution, e.g. at high flow speeds and large volumes, can be implemented via the upstream valves so that power is channeled to the fuel pump where it is needed.

Pump module, can be fitted with a powerful pump or with an additional redundant pump to increase reliability. The pump capacity is designed specifically for the application.

The volume of the cold accumulator containing heat carrier fluid can be adjusted according to the tank cycles and the accumulator can also be refilled via the three-way valve during the ongoing refueling process to achieve efficient back-to-back refueling.

Cooling units can be located away from the fuel pumps. In terms of energy efficiency, distances of usually 50 m are possible. Explosion or noise protection can often be avoided as a result.

Modular system – application spectrum

* Based on current hydrogen projects, for illustrative purposes only.

Customized solutions are developed individually by LAUDA System engineering. Due to the modular system, customized cooling systems can be developed for the respective application within a very short time frame, whether passenger vehicles, trucks, buses, etc.

Pioneering hydrogen refueling for the future of mobility

High-performance hydrogen filling stations are key players in efforts to reduce carbon emissions in the European transport sector. The ›RHeaDHy‹ project, funded by the European Union, is playing a leading role in revolutionizing hydrogen refueling for heavy-duty trucks. We are primarily focusing on developing a high-performance cooling system that forms the basis for high-performance fueling protocols. Intensive simulations are conducted in advance to verify the refueling process that has been developed. The next step will be to install two high-performance refueling systems in France and Germany to test these innovative protocols in practice. The RHeaDHy project, therefore, represents a decisive step in the development of hydrogen refueling systems and paves the way for a promising future in the industry. We are proud to be part of this important process and look forward to shaping the mobility of tomorrow.

Facts and objectives

Acknowledgments and disclaimer

This project has received funding from the European Union’s Horizon Europe research and innovation programme under the HORIZON-JTI-CLEANH2-2022-1 grant agreement No 101101443. The project is supported by the Clean Hydrogen Joint Undertaking and its members. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or Clean Hydrogen Joint Undertaking. Neither the European Union nor the granting authority can be held responsible for them.

Are you looking for temperature control solutions for hydrogen? Then contact us.

Together, we will find the right solution for your requirements.

There are already three products on your comparison list.

To compare other products, please delete one of the products on your comparison list.