In biotechnology, temperature control is essential to the quality of research and production results. Constant temperatures in the operation of bioreactors contribute significantly to the success of the products. As part of sample preparation, there are a variety of work steps that require reliable temperature control.

Research and development

Biotechnological innovations require extensive pioneering work and modern research and development laboratories, independent of whether these innovations involve biopharmaceuticals, bio-based materials or novel foods such as cultured meat. LAUDA laboratory equipment makes work in the molecular biology and biochemical laboratory easier and guarantees precise analytical results that are always reliable and reproducible.

Scale-up

Scaling the bioprocess is a significant challenge along the path to achieving production scale. When selecting suitable bioreactor systems and an appropriate process environment, it is imperative that an adequate yield and degree of quality are ensured. LAUDA offers established solutions for controlling the temperature of different bioreactor types and sizes.

Production

The large-scale manufacture of biotechnological products places significant demands on process control. Precise temperature control is just as important as sophisticated sensor technology and fast communication. LAUDA process thermostats offer maximum precision in temperature control and are easy to integrate into any process environment.

Ultra low temperature applications

Correct handling and storage are crucial to maintaining the stability and effectiveness of biotechnological products such as antibodies, gene therapies and vaccines. Freeze and thaw protocols as well as storage in ultra low temperatures as low as −86 °C are essential. LAUDA offers extremely powerful process thermostats for freeze and thaw applications, tried and tested ultra low temperature upright freezers and chest freezers as well as a mobile innovation in deep-freeze logistics.

Are you looking for the right temperature control system for your biotechnology application? Then get in touch with us right away. We will work with you to find the right solution for your application.

The success of scientific experiments depends to a large extent on careful preparation and precise execution. LAUDA offers an extensive selection of devices for sample preparation and temperature control – both internal and external.

Together with temperature control, shaking is one of the standard operations involved in the production of suspensions, staining and hybridizing or when performing extractions, for example, and can be extremely varied. LAUDA Varioshake shakers are available with an overhead rotating design in addition to the popular bidirectional and orbital shakers. Along with a wide variety of movement options, LAUDA also offers powerful shaking incubators and an extensive range of accessories.

Internal

Water baths and bath thermostats are suitable for controlling the temperature of samples, for example, when incubating biochemical assays or thawing cells. One significant advantage is temperature stability, even when the sample throughput is high. The well-known Alpha, ECO and PRO bath thermostats as well as the Hydro water and shaking water baths from LAUDA provide reliable assistance in every laboratory.

External

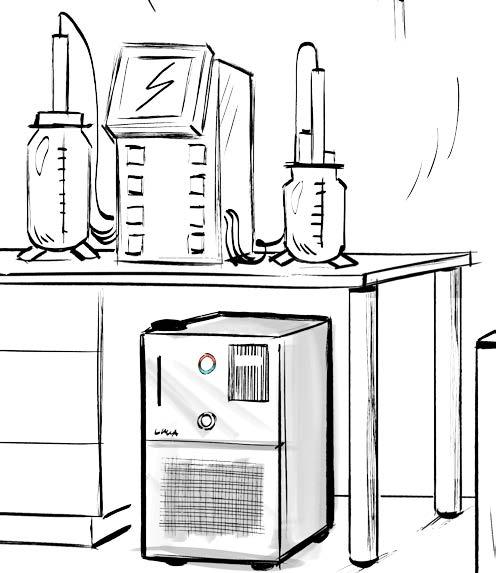

All-rounder: Many LAUDA constant temperature products are suitable for controlling the temperature of laboratory equipment and applications externally. Efficient technologies that can be used flexibly are indispensable in every laboratory.

Benchtop bioreactors present a cost-effective solution for experiments before turning to larger systems. Some of the many advantages include easy cleaning and sterilization, and outstanding flexibility. LAUDA's compact Microcool circulation chillers are suitable for single-walled vessels with a cold finger or double-walled vessels with an integrated heater or heating mat. The LAUDA PRO circulation thermostat is an impressive solution for heating external applications. Are you already familiar with the LAUDA bath thermostats such as the LAUDA ECO? Many LAUDA bath thermostats can also be operated externally and are also suitable for controlling the temperature of smaller bioreactors.

Are you looking for the right temperature control system for your biotechnology application? Then get in touch with us right away. We will work with you to find the right solution for your application.

Compliance with strict acceptance criteria in the validated biotechnological process environment places high demands on the constant temperature equipment used. Even small discrepancies can result in the loss of batches which is both time-consuming and causes significant economic damage. LAUDA offers market-leading and innovative solutions that eliminate the risks resulting from inaccurate temperature control.

Stainless steel bioreactors and fermenters perform extremely well in permanent production processes for biopharmaceuticals, but also in the large-scale production of cultured meat. Available in all sizes, these devices boast individual equipment features and excellent process control.

Single-use technology offers a host of advantages in the production of biopharmaceuticals and also represents a suitable entry-level solution in the production of cultured meat and the fermentative production of recombinant animal proteins. Some of the advantages include no risk of contamination, simplification of time-consuming cleaning validation and low investment costs compared to stainless steel bioreactors.

LAUDA is a complete one-stop supplier of precision temperature control solutions for stainless steel bioreactors and fermenters as well as single-use bioreactors and mixers. LAUDA offers everything from a single source with the established Variocool series for small to medium volumes, the innovative Ultratemp series for large volumes, and a modular system design for individual customer requirements.

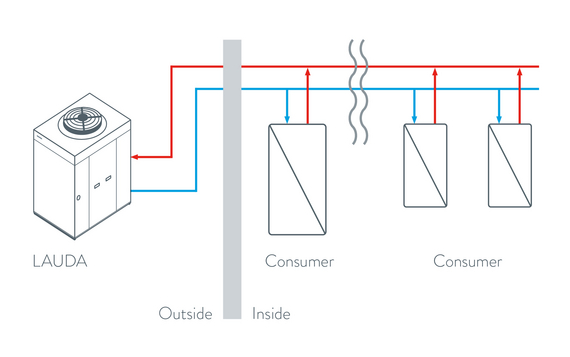

The continuous supply of sufficient quantities of cooling water enables the smooth operation of water-cooled process thermostats, storage tanks and other consumers. LAUDA Ultracool circulation chillers are particularly energy-efficient, scalable and flexible in operation.

Are you looking for the right temperature control system for your biotechnology application? Then get in touch with us right away. We will work with you to find the right solution for your application.

Controlled freezing and thawing as well as storage at temperatures as low as −86 °C are important for maintaining the integrity of biotechnological products, cells and pharmaceutical reference samples. LAUDA offers process thermostats for controlled freezing and thawing as well as solutions for ultra low temperature storage and logistics.

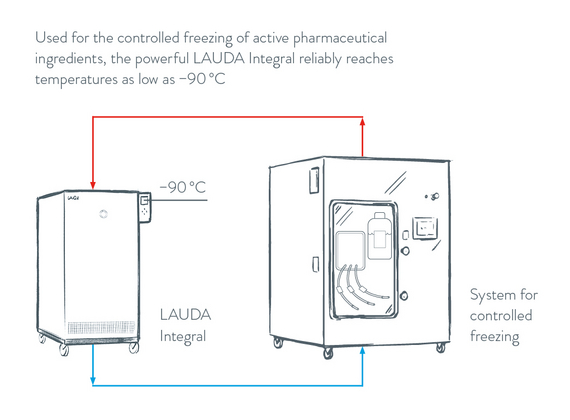

Freezing and thawing at defined cooling and heating rates has become an indispensable process in the treatment of valuable biopharmaceutical products. The process simplifies handling during essential transport phases and guarantees consistent product quality. Modern systems enable full integration into the process chain, a high level of automation and therefore increased safety and control.

Highest performance requirements for cooling

High cooling rates, rapid response times, and complex hydraulics at temperatures below −80°C. The constant temperature equipment must be able to cool dynamically, and must feature powerful, variable pumps that can also handle high flow resistances.

Deep process integration

Reproducible results can only be guaranteed through a perfect connection between the constant temperature equipment and the freeze and thaw unit, as well as easy readability for monitoring and process optimization purposes. The innovative flow principle and eight-stage Vario pump on the LAUDA Integral XT enable high dynamics, even with complex hydraulics.

Ultra low temperatures below −80°C are essential for ensuring the stability, integrity and effectiveness of biopharmaceutical products and cells over a longer period of time. Any interruptions in the ultra low temperature storage of therapeutic proteins, genetic material, cell lines or even reference samples represent an economic risk and a product risk and can lead to complicated checks and special approvals.

LAUDA Versafreeze upright and chest freezers offer safe storage of valuable samples and biopharmaceuticals.

Today, deep-freeze logistics in the biopharmaceutical industry rely on the use of latent heat accumulators (PCMs) or dry ice. However, both applications have serious limitations. While PCMs are only available for ultra low temperature applications to a limited extent, dry ice maintains the temperature at −78.5 °C through sublimation. Handling dry ice runs the risk of suffocation, frostbite and explosion. The continuous procurement of dry ice along with the implementation of measures to counter any risks also generate high running costs.

LAUDA Mobifreeze is the world's first ultra low temperature chest freezer that can be connected to the power supply or operated by battery. The solution eliminates the need for dry ice and PCMs, is ready for use at any time and enables flexible configuration of temperature settings for the relevant product. This means that transportation can take place under the validated storage conditions.

You can find out which devices and solutions we can support you with in the field of biotechnology in our new brochure.

In accordance with the principle of ›modular engineering‹, LAUDA systems are planned and built precisely according to customer‘s wishes: process-oriented, customized and with precision control,meeting the strictest safety standards.

Answer some questions and we will work out your individual constant temperature solution in the next step.

You are looking for Measuring instruments that combine precision, reliability and longevity confidently?

There are already three products on your comparison list.

To compare other products, please delete one of the products on your comparison list.